Electronic endoscopic equipment is vital in minimally invasive surgery, transmitting clear images of the patient’s body for doctors, facilitating intraoperative observation, lesion navigation, and diagnosis and treatment operations. Endoscopes can be divided into complex mirrors and soft mirrors according to whether the mirror body bends and enters the human body. On the one hand, as high-end medical equipment, the domestic endoscope market, whether soft or hard, has been dominated by overseas giants for a long time. On the other hand, the national policy encourages domestic equipment and favors it from registration to purchase. Against such a background, we can’t help but ask, “Can the endoscope track become the next domestically-made replacement’s early value depression?”

From the technical level of the looking glass industry, we can see the technological trend of soft and hard mirror equipment and the technical group of domestic leaders.

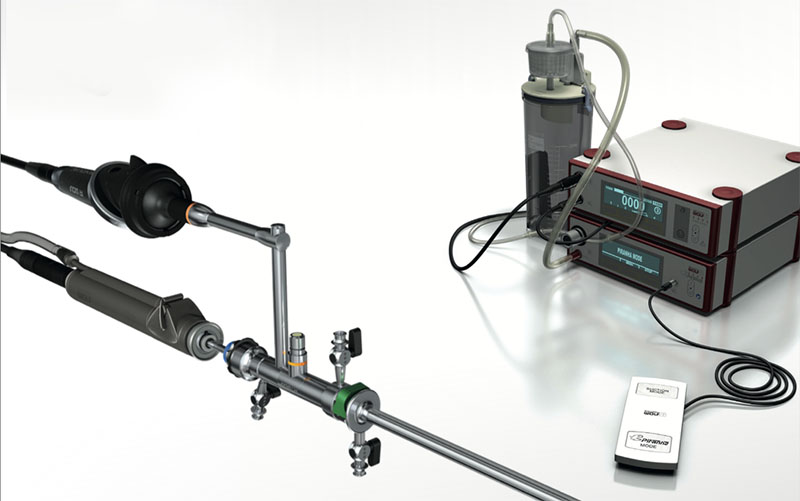

Technical level: Gradually break through the technical blockade and move towards domestic substitution. The technical focus of complex mirrors and soft mirrors are slightly different. The homogeneity of the hard mirror upstream is serious, and the midstream complete machine manufacturers pay more attention to the camera system of the endoscope. The core technology focuses on image processing functions under the integration of hardware and software such as fluorescence, 3D, and 4K. The overall hard mirror technology trend is mainly concentrated in:

1) In terms of image sensors, CMOS will gradually replace CCD, laying the foundation for domestic substitution;

2) In terms of AI ISP image signal processing, AI+ image processing analysis will be an important direction for future technological development;

3) In terms of fluorescence endoscopy, the fluorescence processing system is a global technological iteration trend, and leading domestic brands are expected to usher in;

4) Regarding mirror bodies, the technical barriers of rigid mirror bodies lie in optical technology and precision manufacturing. Relying on the first-mover advantage, imported manufacturers have fully covered mirror bodies and camera systems. A small number of departments still dominates domestic products and are accelerating the realization of a full-category range;

5) In terms of complete machines, accelerated R&D and differentiated innovation will speed up the process of domestic substitution. The overall cost performance of domestic products is remarkable, and innovative image processing technology can enhance the bargaining power of the whole machine. The industry chain of soft mirrors is more complicated than hard mirrors, involving the independent manufacturing of multiple modules and components. The core technology focuses on image processing functions such as ultrasound, magnification, and electronic dyeing technology, as well as the flexibility of mirror body manipulation.

The overall soft mirror technology trend mainly focuses on:

1) In terms of image processors, domestic electronic dyeing technology has broken through the monopoly of NBI patents;

2) In terms of enlargement, the gap between domestically produced and Aohua gradually narrowed with imports;

3) Disposable soft mirrors are the deterministic direction of future device innovation, and domestic manufacturers are accelerating their deployment;

4) Ultrasound assists in precise diagnosis and treatment, and domestic production has core competitiveness;

5) In terms of mirror body, the soft mirror body tends to pursue the ultimate controllability and the invisible gap between imported and domestic brands is highlighted. In addition, imported lenses cover a more comprehensive range than domestic ones, and domestic brands are also speeding up their coverage;

6) Regarding complete machines, domestic performance is gradually catching up with imports, and the price/performance ratio is remarkable. It is expected to continue to increase in volume in the future. Both domestic hard and soft mirrors are pursuing independent and controllable supply chains and carrying out differentiated technological innovations to accelerate the process of domestic substitution.