Regardless of the grade of CT scanners, the essential clinical requirements for CT scanners are the same: high performance, high stability, high-definition images, high-throughput inspection, high service quality, and low maintenance cost.

The first four items are for the equipment itself:

1) High performance requires high hardware configuration, which means the cooperation of high-speed racks, high-power, high-voltage generators, large heat capacity tubes, and high-quality detectors;

2) High stability requires reasonable hardware layout and good software optimization, which means that the whole machine has no shortcomings, especially the tube must be durable.

3) High-definition images require reasonable kV, mAs, and reconstruction algorithms, which means the cooperation of high-voltage generators, tubes, detectors, and reconstruction algorithms;

4) High-throughput inspection requires fast scanning speed and short scanning interval, which means the cooperation of a high-power, high-voltage generator, large heat capacity, and long-life tube;

Therefore, to better meet users’ needs, high-quality CT scanner still needs high-quality tubes, high-voltage generators, and detectors. For a long time, the market has focused on the number of detector rows, which has been used as an essential basis for evaluating CT scanners performance. However, compared with the detector, the tube is the core device for generating X-rays, and its quality directly affects the running speed, imaging effect, and service life of CT, which is the key to ensuring the performance of clinically applicable CT. In addition, in recent years, the amount of CT examinations has increased significantly. At most, 200-300 people undergo tests every day in outpatient clinics. This massive patient flow puts forward higher requirements for the speed, stability, and durability of CT. Only a robust tube can support high-throughput inspections and solve the most urgent clinical problems. Therefore, the three most essential points of clinically applied CT are the tube, the tube, and the tube.

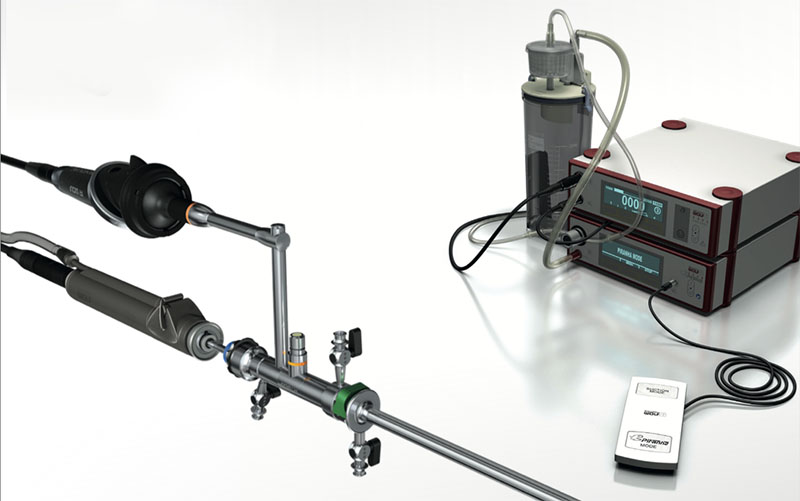

2. Liquid metal bearing tube VS ball bearing tube

Traditional ball-bearing tubes have obvious performance disadvantages when faced with large-flux scanning:

1) The ball point contact structure leads to poor heat conduction and heat dissipation of the bearing, and it is necessary to pause during the scanning interval to wait for the tube to cool down, which reduces the patient turnover;

2) The anode rotation stops after each scan, and the workflow is poor, which affects the scanning efficiency;

3) Generally, the service life is short, and the tube needs to be replaced many times during the life cycle of CT equipment, which increases the cost of use;

4) Severe wear and tear, prone to card rotation and other failures, causing the hospital to shut down for maintenance and affecting operational efficiency.

The liquid metal bearing ball tube, which represents the highest technical level of the ball tube, is filled with liquid metal between the rotor and the bearing to replace the steel balls, changing from a rolling bearing to a sliding bearing. There is almost no friction during operation, comparable to a mechanical ball-bearing ball tube. The performance advantage is outstanding, which also makes CT more clinically valuable:

1) Strong heat dissipation and large flux: It has higher heat conduction and cooling capacity, realizes 360-degree all-round heat dissipation, ensures continuous ultra-high-throughput scanning, and quickly realizes daily inspections of hundreds of patients;

2) Long service life and low cost: there is almost no wear and ignition failure, the service life is significantly extended, and the operating cost of the hospital is significantly reduced;

3) High heat capacity and high power: With ultra-high heat capacity and high power stable output, it can provide 0.49s/360°+0.5mm thin-layer high-quality images and can complete the whole lung scan within 7 seconds;

4) No start-up, fast process: the anode keeps continuous and high-speed rotation during operation, with no need to wait for the anode to reach the specified speed, and improves patient turnover;

5) No noise, excellent experience: There is no friction during operation, and almost no noise and vibration are generated, giving patients a comfortable inspection experience.

3. New standard equipment for clinically applied CT

Due to the wear-free operation, there is almost no waiting for patients to scan, simplifying the hospital workflow. The liquid metal bearing ball tube can not only respond faster to the equipment and adapt to the needs of high-throughput inspections but also achieve better cardiac imaging capabilities, more comprehensive The dynamic coverage range meets the application of functional imaging such as perfusion and dynamic blood vessels. It becomes the “exclusive customization” of high-end CT with 64 rows and above.

However, with new regulations on CT scan appointments and waiting time, the efficiency of CT diagnosis and treatment in primary medical institutions is also facing more significant challenges. Therefore, the advantages of large heat capacity liquid metal bearing tubes should also be applied to clinical CT. For example, according to a tube stress test: when using typical chest scan parameters (34.7kw, 6.3s) for continuous scanning, the liquid metal bearing tube can be more effective than the ball bearing tube. Scan nearly 40% to 80% of patients. However, due to the high technical barriers of liquid metal bearing tubes, much research, development, and mass production know-how is required. The production process involves more than 30 processes, and the critical technical problems encountered include design, materials, processing, and welding. , Vacuum, surface treatment, precision assembly, and other aspects, the process is challenging. Therefore, such tubes are seldom configured on clinical CT scanner.